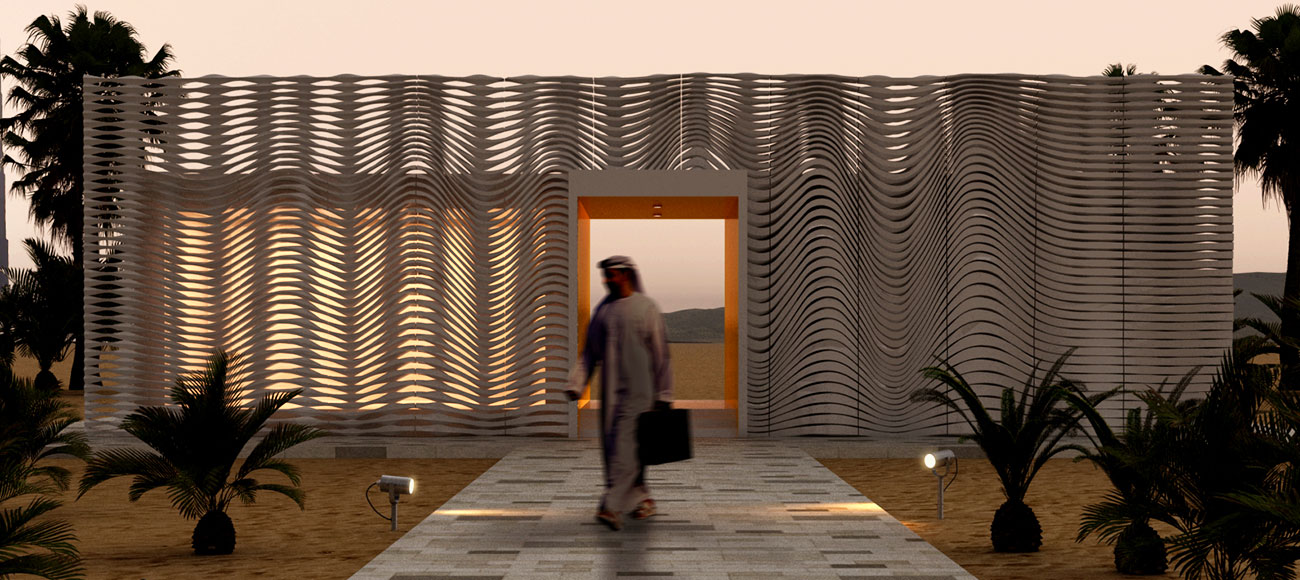

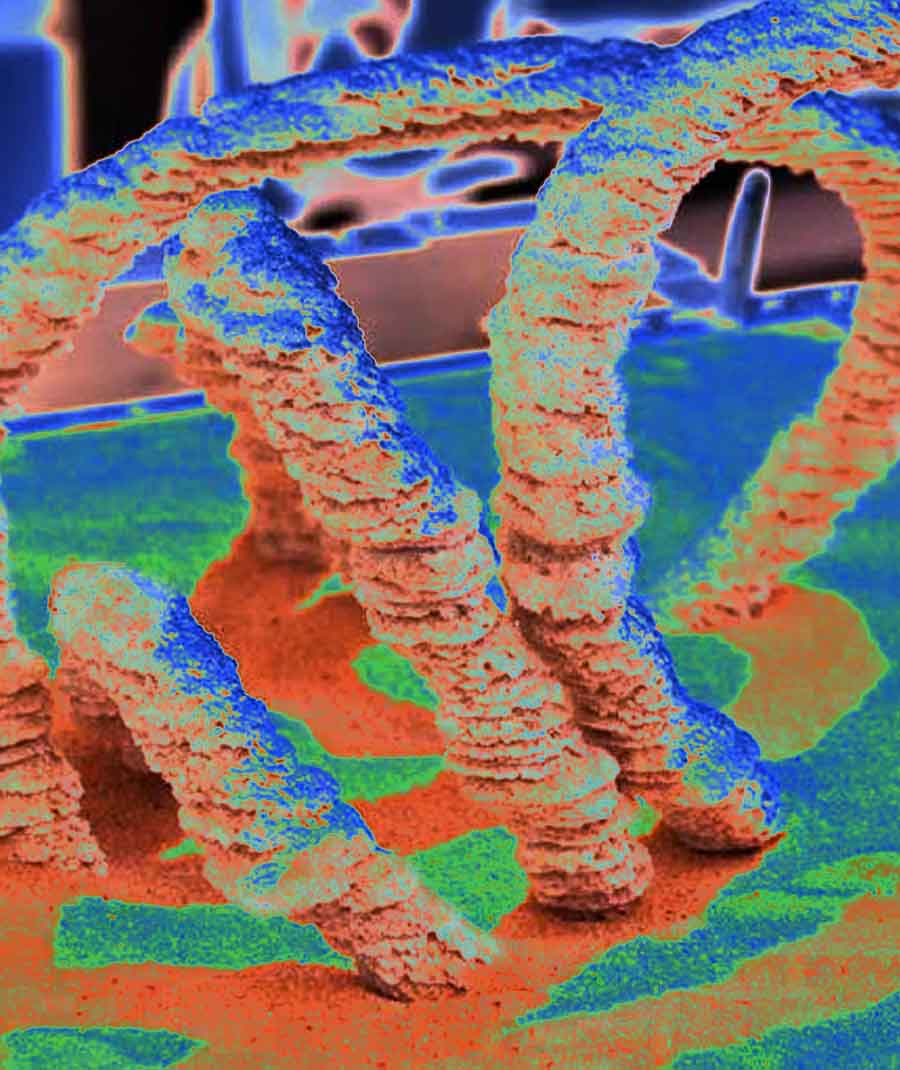

The research hereby proposed illustrates the project of a 3D printed facade shading system for a service pavilion at Expo 2020 in Dubai, the design is easy replicable and can be feasible also for other overlay spaces. Hence the design for this facade had to fulfill the typical features of temporary architecture for Expo: lightweight (ease of transport and on-site construction), modularity (easy assembly and designed for production), flexibility (ability to cover many functions and to adapt to different constraints), identity (reflection of the identity of the hosting country). The concept, is inspired by the local environment and architecture: the pattern is created by the winds drifting through the dune sand related to the tradition of filtering light and creating privacy through ornamental screens. Algorithms modulate landscapes of curves, which are materialized into three-dimensional geometries displaying gradients of porosity, curvature, and thickness. Hence it is possible to physically “slide” these parameters on the Grasshopper definition that assess the design.Through computational design the facade concept has been optimized for additive manufacturing. Many tests have been conducted on polymeric printable materials, through a climatic chamber in Politecnico di Milano (Laboratorio Prove Materiali), to ensure material performances and durability at high temperatures. Then a campaign of digital fabrication tests has been started to optimize, simultaneously, the shape of the facade and the printing settings (such as retraction value, layer height, speed)

Desert Tectonics

3D PRINTED SHADING SYSTEMRELATED PUBLICATIONS

ABOUT LARGE-SCALE POLYMERS PRINTING IN ARCHITECTURE:

- T. D. Ngo, A. Kashani, G. Imbalzano, K. T.Q. Nguyen, D. Hui, Additive manufacturing (3D printing): A review of materials, methods, applications and challenges, Composites Part B: Engineering143 (2018) 172-196 https://doi.org/10.1016/j.compositesb.2018.02.012

- I. Hager, A. Golonka, R. Putanowicz, 3D Printing of Buildings and Building Components as the Future of Sustainable Construction?, Procedia Engineering, 151 (2016) 292-299 https://doi.org/10.1016/j.proeng.2016.07.357

- R. Naboni, A. Kunic, I Paoletti. Load-responsive skin systems for lightweight architecture(2016) Conference: 11th Conference on Advanced Building Skins, Bern

- M. V. Sarakinioti, M. Turrin, T. Konstantinou, M. Tenpierik, U. Knaack, Developing an integrated 3D-printed façade with complex geometries for active temperature control, Materials Today Communications 15 (2018) 275-279 https://doi.org/10.1016/j.mtcomm.2018.02.027

- Department of Architecture TU Munich, https://www.ar.tum.de/en/hk/news-single-view-en/article/fluid-morphology-3d-printed-functional-integrated-building-envelope/ (accessed 28 Dicember 2018)