Abstract: The conventional construction methods pose several environmental issues such as generating heat, pollution and waste. Furthermore, the production of established construction materials heavily relies on the extraction of non-renewable resources. The growing population and in turn, growing need for more construction set an almost insurmountable challenge for the practitioners and the industry as a whole. In order to address these issues, several concepts and models of practising have been formulated by scientists. The concepts include Circular Economy, Cradle to Cradle, Upcycle, Bio-fabrication and Augmented Age. The concepts have inspired the adoption of discoveries and contributions of other disciplines such as biology, mycology and mathematics.

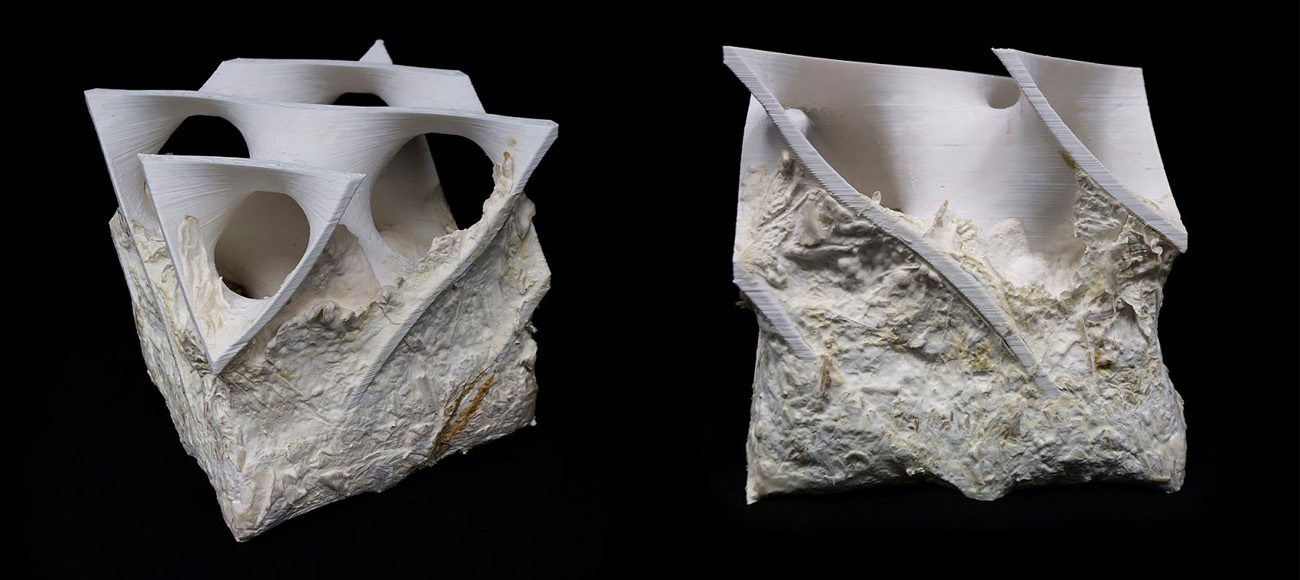

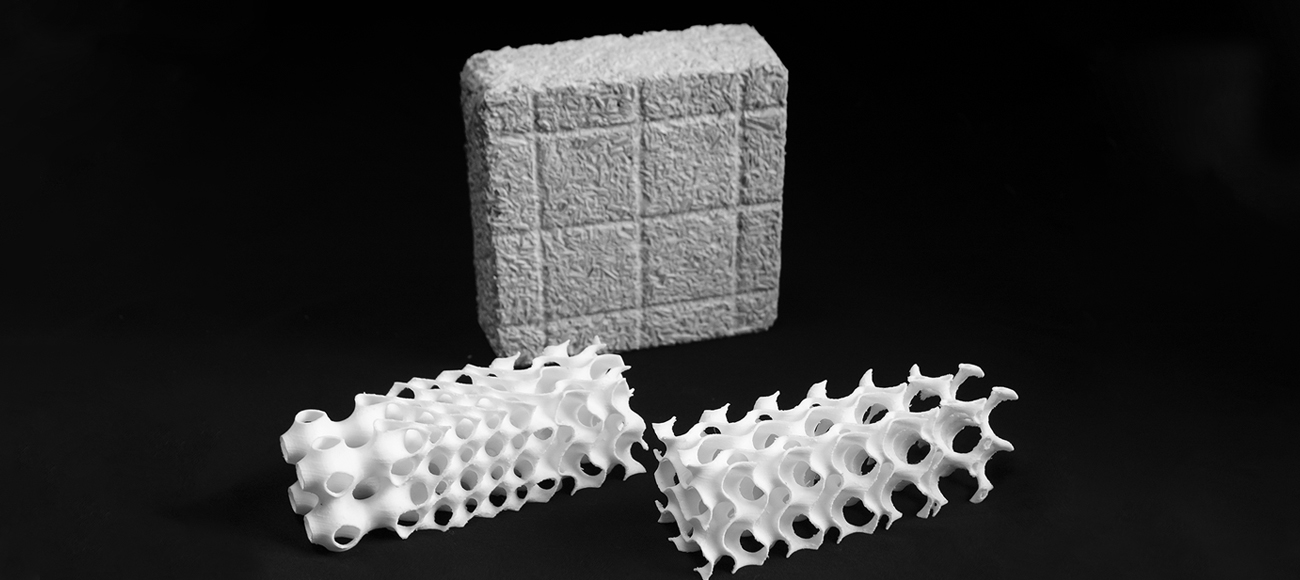

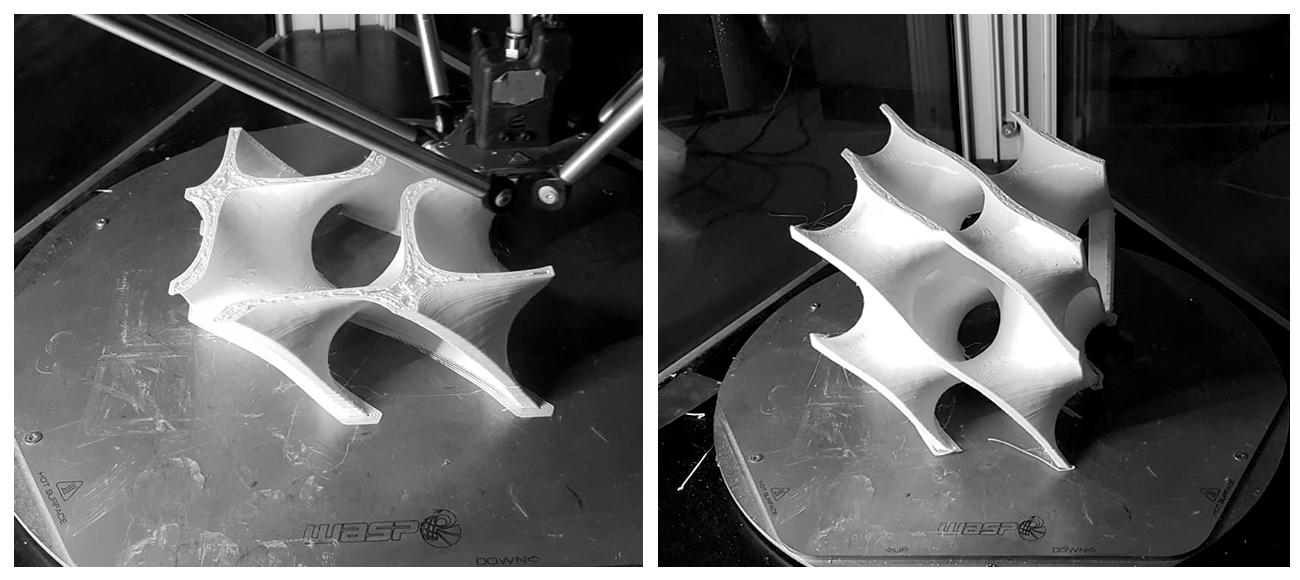

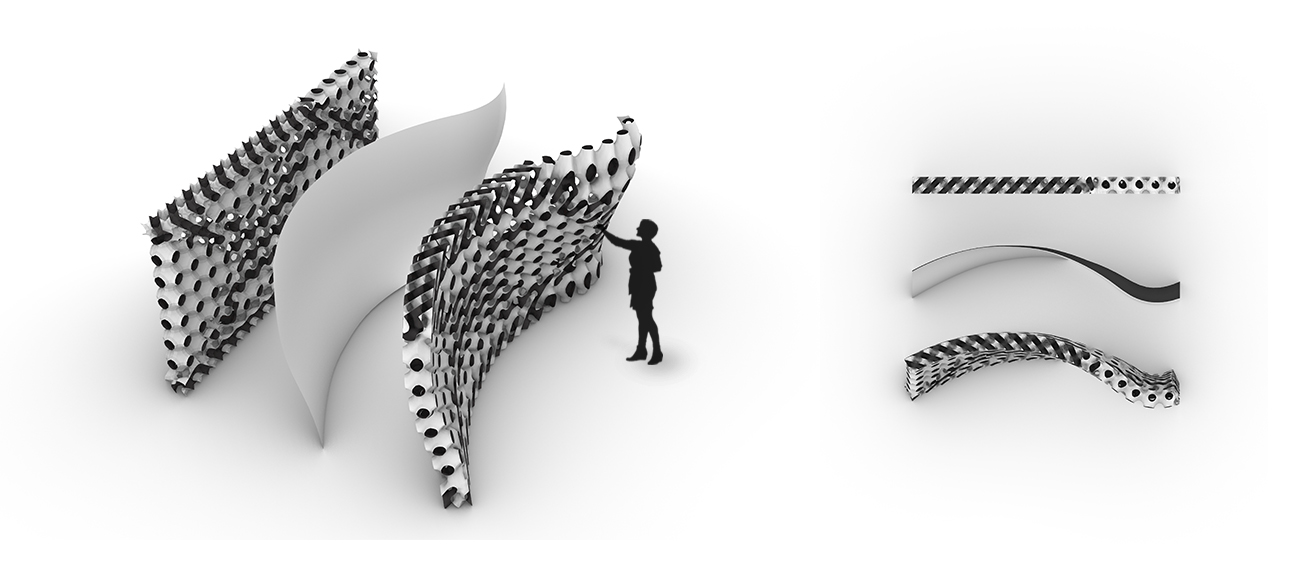

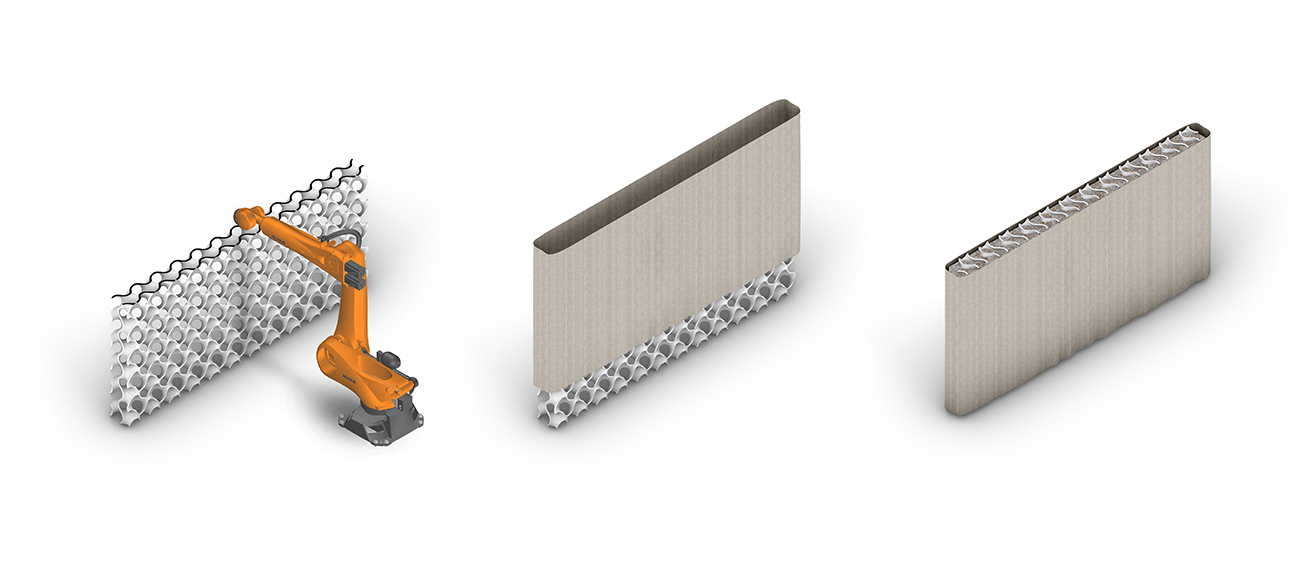

Mycelium composite is a promising alternative material in terms of thermal and acoustic as well as fire safety performance. It exhibits exceptional end-of-life stage, replenishing the soil as it completely composts after disposal. However, it is suggested that mycelium composite still does not qualify as a structural material. For this reason, an adaptive lattice structure system is proposed based on the literature on the family of cellular structures as a light-weight and porous structural component that can host mycelium composite material. The study on the types of lattice structures led to the adoption of Triply Periodic Minimal Surfaces as the solution for the adaptive lattice structure. Manufacturing of these surfaces is not possible with conventional manufacturing techniques. The rise of additive manufacturing technologies, however, enables the production of highly complex topologies including Triply periodic minimal surfaces. Assuming the possibility of adoption of AM technologies in the future of the construction industry, the project opts for BAAM (Big Area Additive Manufacturing) using Plastic. The plastic is proposed to be derived from plastic waste and converted into Printing filament for Additive manufacturing using a filament producing technology developed by Filabot Company. The result is expected to be a light-weight fully circular construction system that can be adopted in future construction practices.

Keywords: Circular Economy, Waste, Cradle-to-Cradle, Bio-Fabrication, Mycelium, Lattice Structure, Additive Manufacturing, Triply Periodic Minimal Surfaces