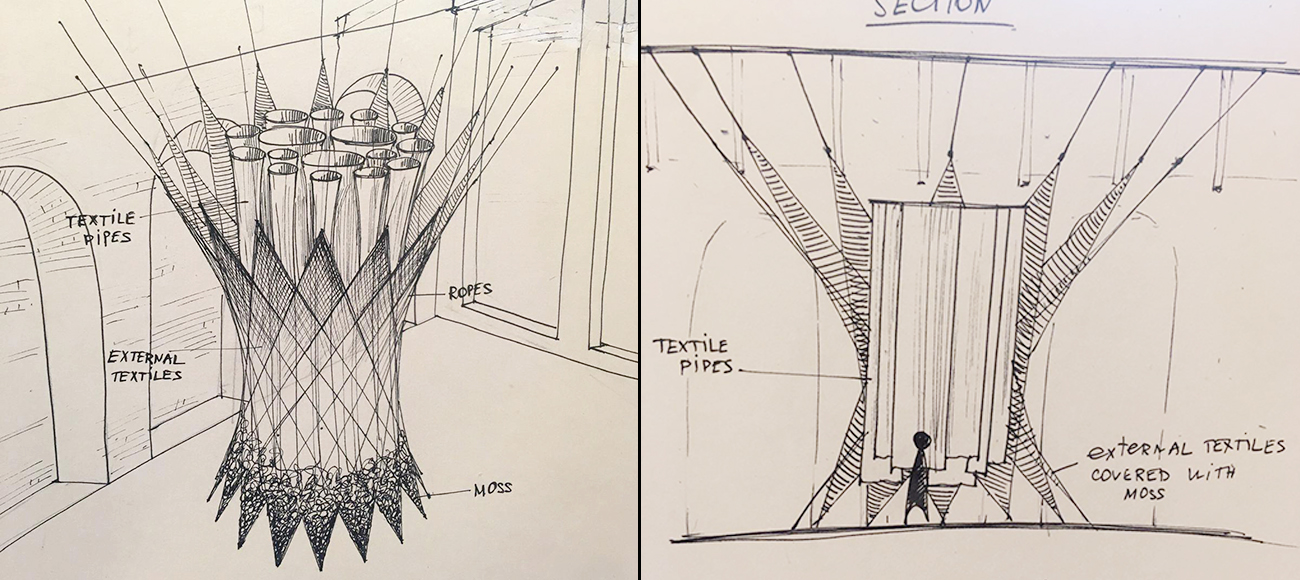

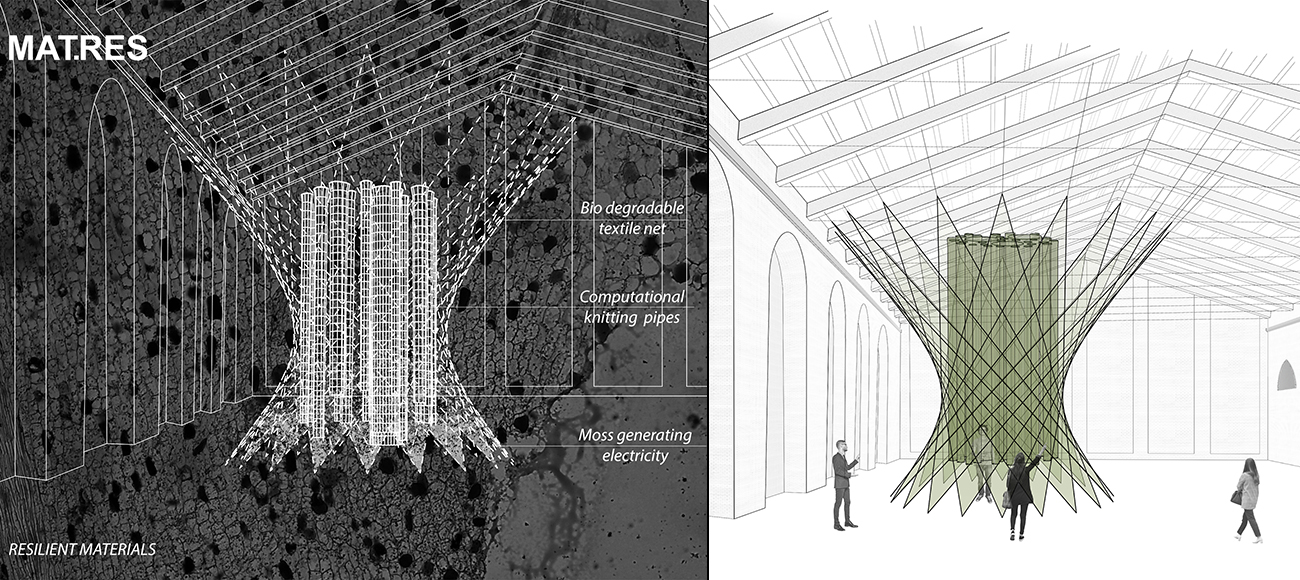

MATRES is an installation presented at the 17th International Architectural Exhibition Biennale di Venezia. MatRes is a living laboratory of resilient materials, with a biological, organic, sustainable, recycled origin, which has a voice and the freedom to grow and transform over time. The installation aims to evoke the metaphor of a tree, experiencing its resilient forms and materials that compose it.

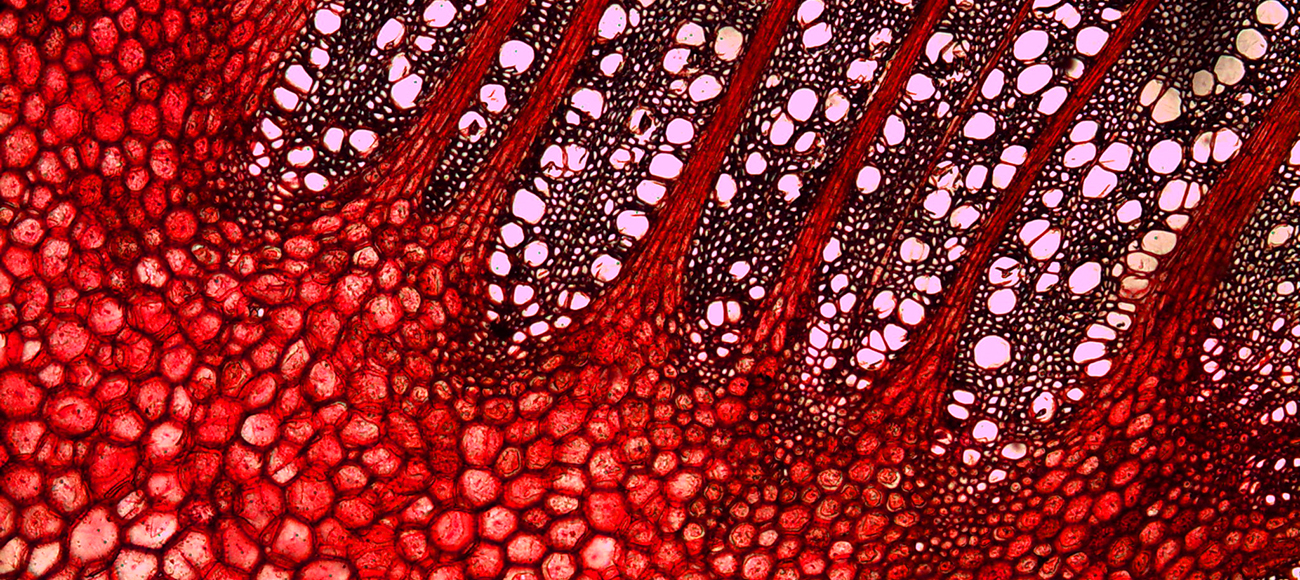

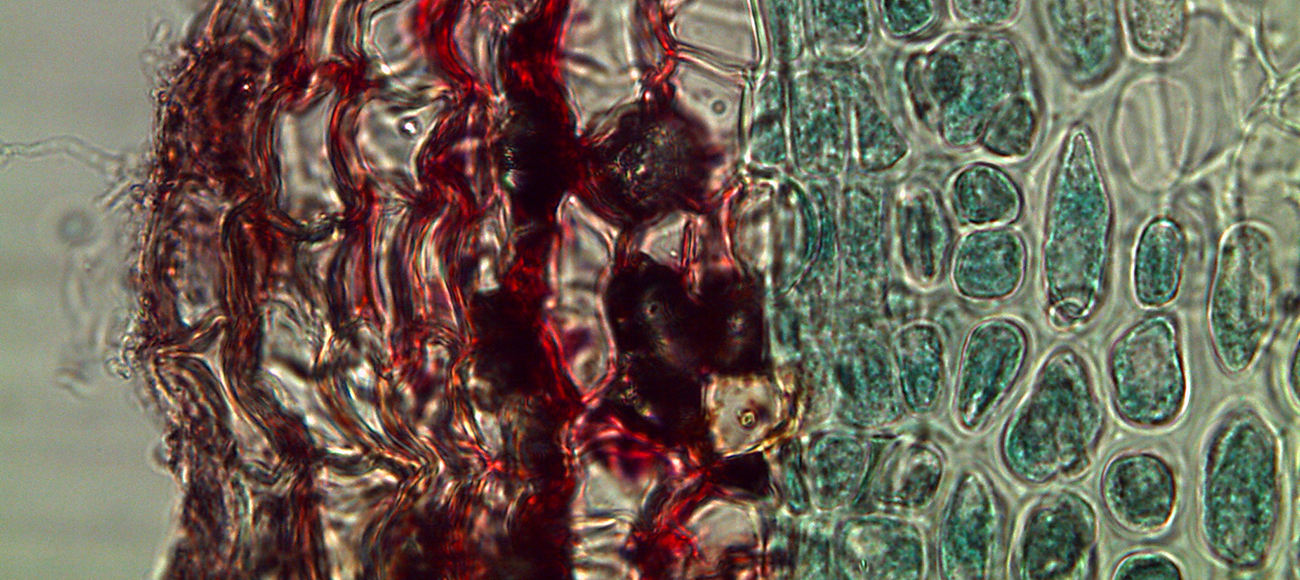

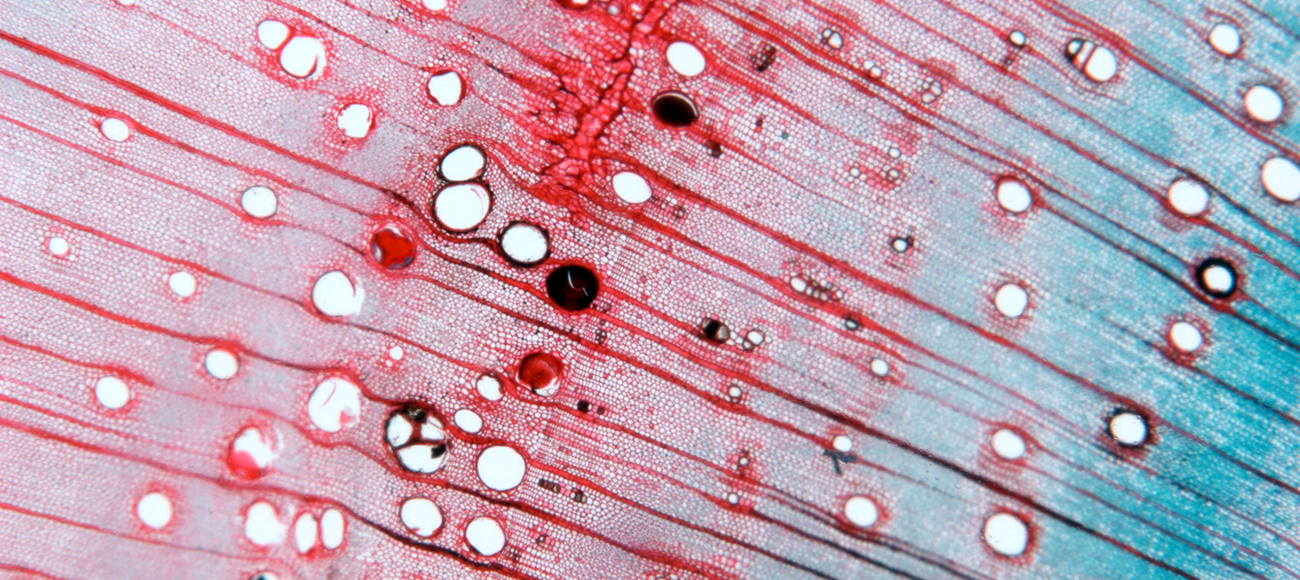

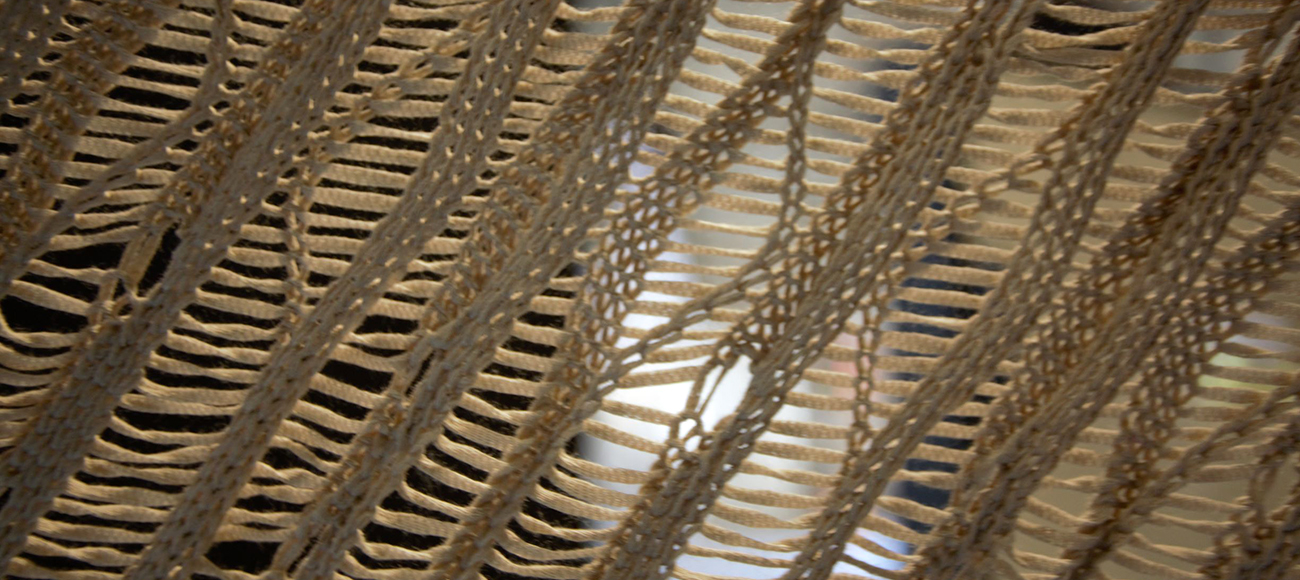

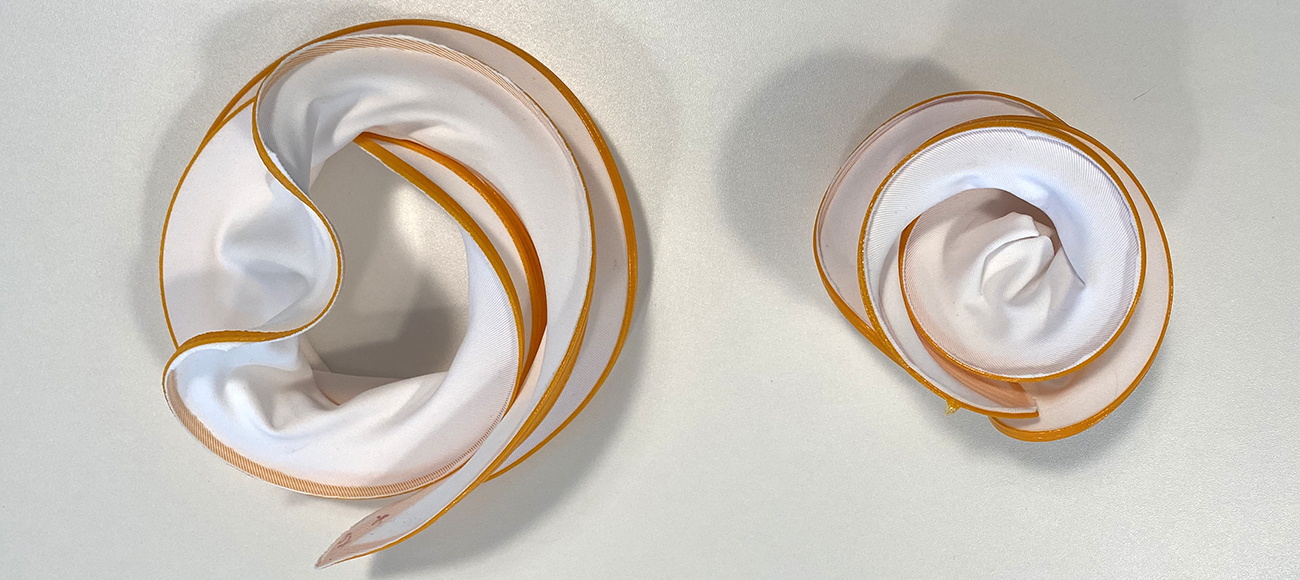

MaTres tells the resilient behavior of the wood fibers, of the longitudinal and transverse vessels, of the central pith and the bark, through the use of materials that come from the culture of architecture, interior spaces, fashion. From natural composite materials (mycelium, coffee waste, cellulose) to 4D printing, from plants that produce energy to fabrics with optical, acoustic, or thermosensitive properties to natural or recycled fibers, reacting virtuously to stressful stimulations.

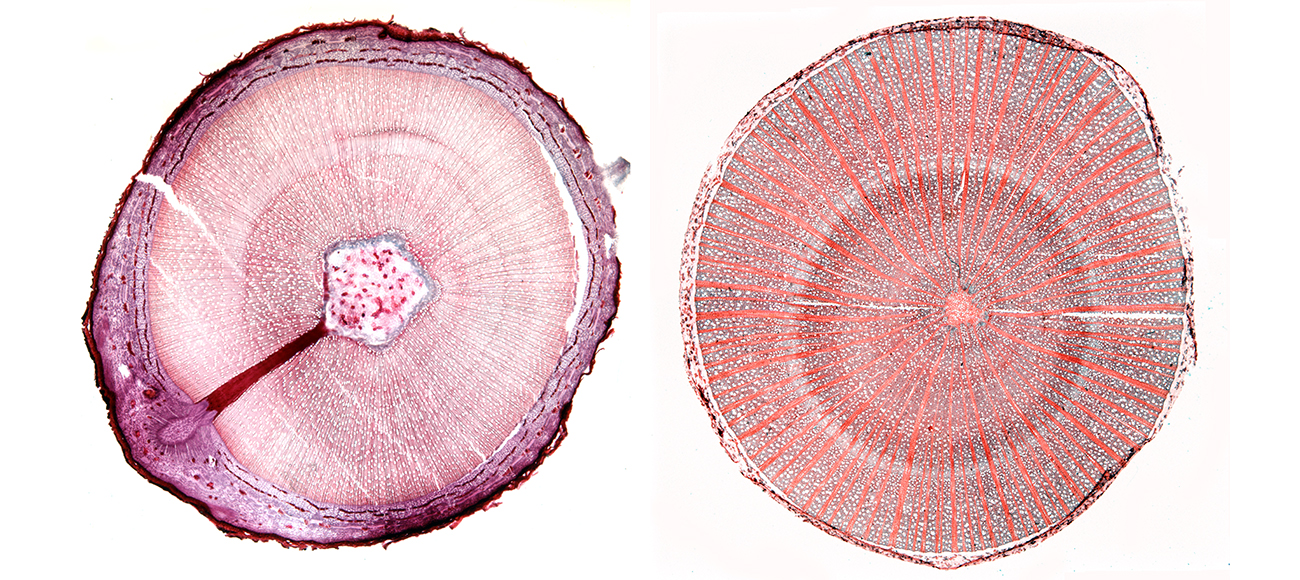

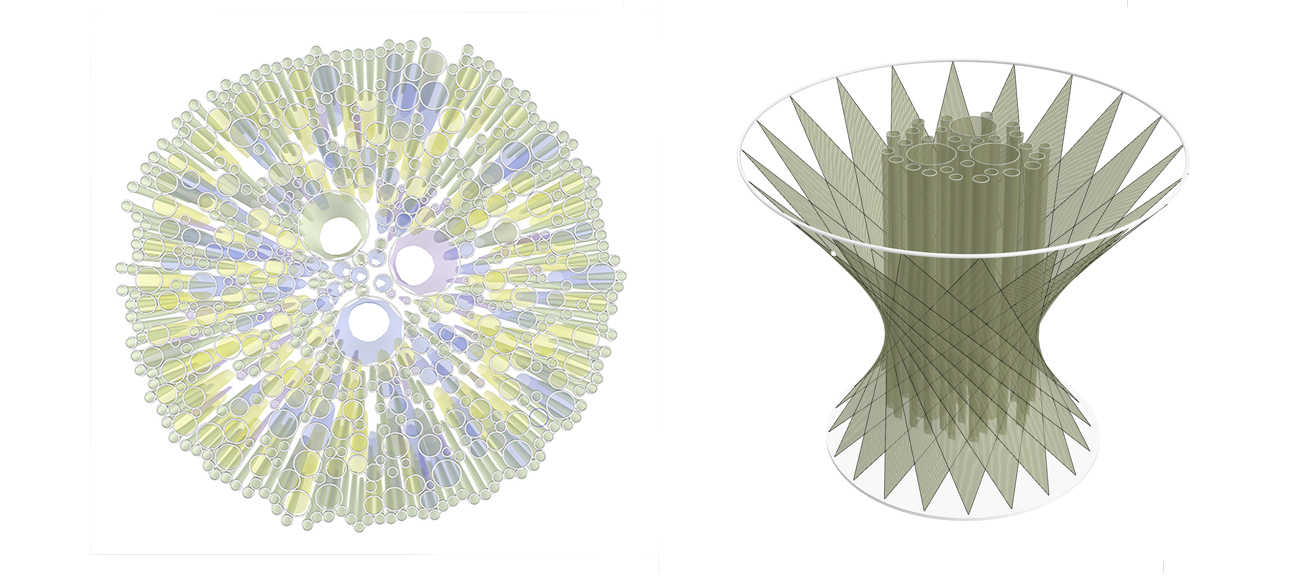

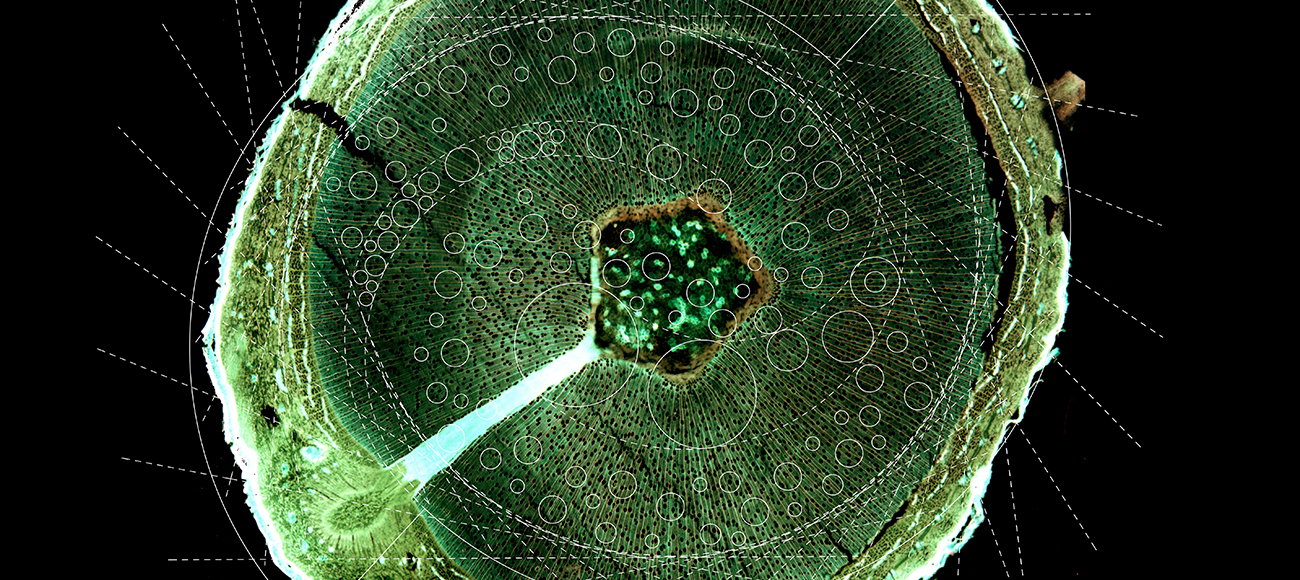

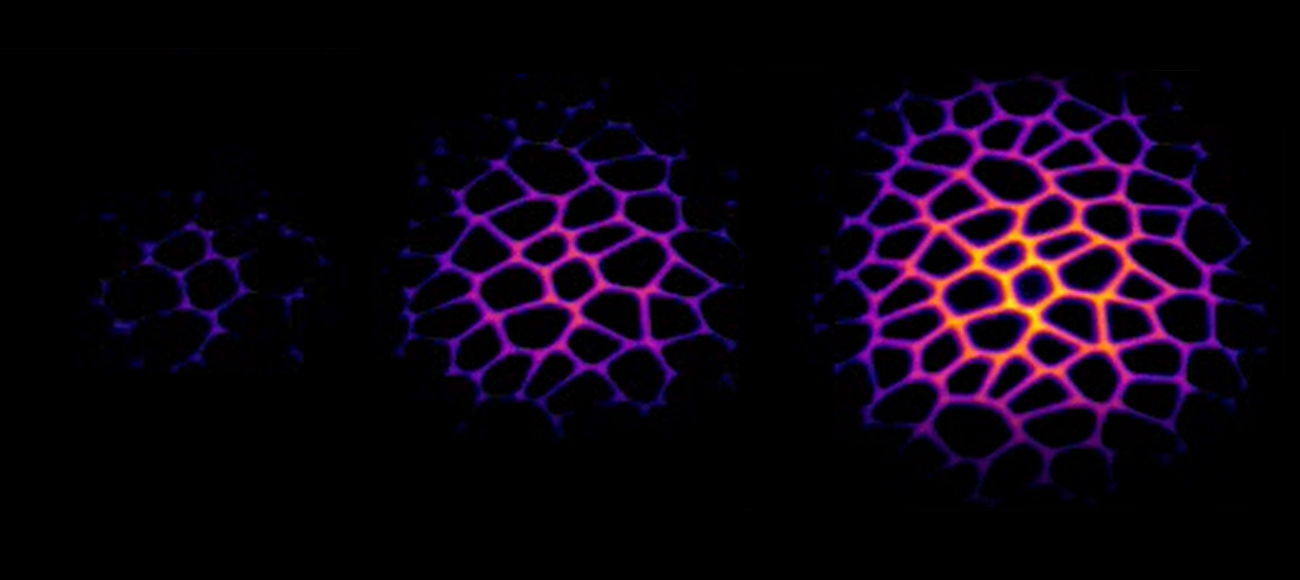

A trunk of a tree with its fibrous structure is made up of cells linked to each other by a network of macromolecules that regulate their proliferation, development, and differentiation constitutes a resilient micro-architecture par excellence. An immobile organism like a plant generates over time a system of strategies capable of transforming adversity into vital advantages. Learning from these resilience models allows us to develop advanced construction systems (material resiliency).

The environments in which we live, and the materials that make up the scenarios of the near future, must have high resilience to the increasingly unpredictable and extreme conditions of climate and weather. Materials must protect ecosystems from exogenous attacks, must be able to absorb the impact of radical transformations and change irreversible paradigms into new forms of life. From resilient materials, the subsequent transformation of spaces, places, and relations between the natural and built environment will begin.

A new architecture will start from the chemistry and biology of materials, give them voice and body, follow their performance, reversing their functional and ancillary relationship which are now exhausted. Designing with resilient materials means assuming them as actors and protagonists with their forms, behaviors, qualities, temporality, intentionality, and not vice versa.

The origin, the study under the microscope, the computational design, the life cycle of the materials used for the installation, start a resilient design model to be made available for a conscious and responsible future. In this politics of the matter, the choices will be guided by the environment, nature, and life, which will cross in a new continuum, creating an increasingly integrated and resilient system.

The research of the Material Balance Research group concerns the development of these new responsible materials on an environmental, architectural, and technological scale. Through the definition of a new design paradigm, we intend to promote a homeostatic relationship with the environment that preserves resources and at the same time reduces waste. Some experiments carried out by the group are exhibited within the installation set up in the Italian Pavilion of the Venice Biennale.